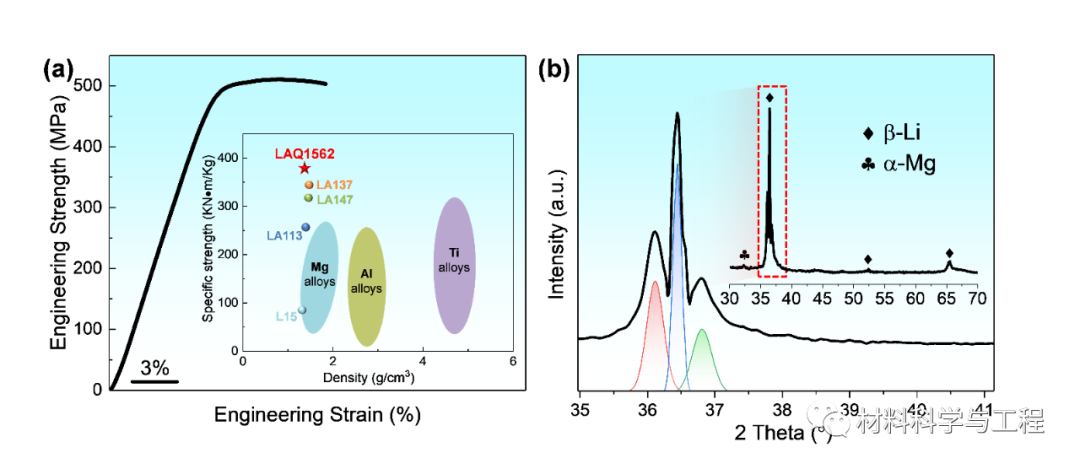

鎂鋰合金是世界上最輕的金屬結(jié)構(gòu)材料,具有低密度(1.3-1.65 g/cm3)、高比強(qiáng)度、高比剛度等特點(diǎn),擁有良好的導(dǎo)電導(dǎo)熱性能、突出的阻尼性能、優(yōu)異的電磁屏蔽性能等諸多優(yōu)勢(shì)。當(dāng)鋰含量超過(guò)10.3 wt.%時(shí),鎂鋰合金基體將由HCP-α相轉(zhuǎn)變?yōu)?/span>BCC-β相,該相變(HCP→BCC)可以進(jìn)一步降低合金的密度且顯著提高鎂鋰合金的塑性和冷加工能力。因而BCC鎂鋰合金成為結(jié)構(gòu)輕量化的理想材料,可以推動(dòng)航空航天、汽車(chē)等領(lǐng)域的輕量化發(fā)展,助力“雙碳”目標(biāo)實(shí)現(xiàn)。然而,絕對(duì)強(qiáng)度低和熱穩(wěn)定性不足嚴(yán)重制約了BCC鎂鋰合金的廣泛應(yīng)用。合金元素鋁是BCC鎂鋰合金中最有效的沉淀強(qiáng)化元素,項(xiàng)目團(tuán)隊(duì)前期研究發(fā)現(xiàn)BCC鎂鋰鋁合金中的強(qiáng)化效應(yīng)源于調(diào)幅分解誘導(dǎo)的納米富Al團(tuán)簇[1]及其有序相變形成的納米亞穩(wěn)強(qiáng)化相 D03-Mg3Al;在β單相區(qū)內(nèi)增加Li和Al含量可以設(shè)計(jì)出輕質(zhì)、高強(qiáng)、室溫?zé)岱€(wěn)定性?xún)?yōu)異的BCC鎂鋰合金[2]。如何進(jìn)一步提高BCC鎂鋰鋁合金的強(qiáng)度及其高溫?zé)岱€(wěn)定性,成為拓展其在航空航天領(lǐng)域應(yīng)用的關(guān)鍵問(wèn)題。針對(duì)上述問(wèn)題,南京理工大學(xué)聯(lián)合香港大學(xué)、西北工業(yè)大學(xué)、重慶大學(xué),設(shè)計(jì)了Al-Ag協(xié)同合金化的BCC鎂鋰合金。研究結(jié)果表明,設(shè)計(jì)的鎂鋰鋁銀合金的屈服強(qiáng)度達(dá)到500 MPa左右,其顯微組織展現(xiàn)了鋁-銀共偏聚以及基體鋰元素的再分布特征。BCC鎂鋰鋁銀合金的高強(qiáng)度源于上述組織引起的共偏聚團(tuán)簇強(qiáng)化與共格應(yīng)變強(qiáng)化,其中團(tuán)簇錯(cuò)配強(qiáng)化占主導(dǎo)。本工作提出了利用協(xié)同合金化設(shè)計(jì)超輕高強(qiáng)BCC鎂鋰合金的新策略,為鎂鋰合金的高性能應(yīng)用奠定基礎(chǔ)。相關(guān)成果以題為“Achieving high strength via solutes co-clustering and solvents redistribution in an ultralightweight BCC magnesium alloy”發(fā)表于國(guó)際材料頂刊Materials Research Letters。論文第一作者為南京理工大學(xué)唐頌副教授,通訊作者為香港大學(xué)辛同正研究員,南京理工大學(xué)蘭司教授、寇宗德博士,西北工業(yè)大學(xué)羅婷教授。https://www.tandfonline.com/doi/full/10.1080/21663831.2023.2188909圖1. BCC鎂鋰鋁銀合金力學(xué)性能及XRD譜圖

圖2. BCC鎂鋰鋁銀合金三維元素分布及其二維成分等高圖

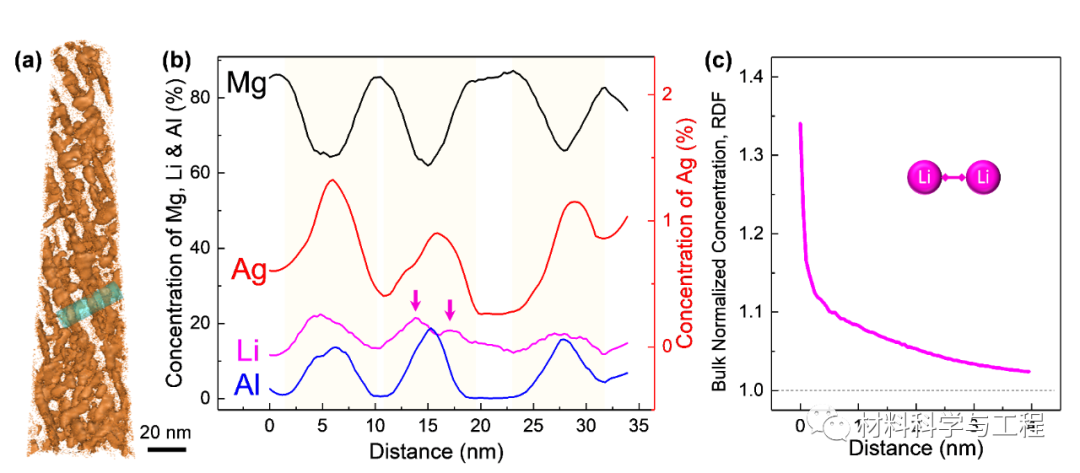

圖3. BCC鎂鋰鋁銀合金HAADF-STEM及EDS能譜圖圖4. BCC鎂鋰鋁銀合金10at.%Al等成分面圖、一維成分分析及Li-Li RDF圖以上工作得到國(guó)家重點(diǎn)研發(fā)計(jì)劃課題、國(guó)家自然科學(xué)基金、江蘇省自然科學(xué)基金、中央高校基本科研業(yè)務(wù)費(fèi)等項(xiàng)目支持!近年來(lái),項(xiàng)目團(tuán)隊(duì)有關(guān)BCC鎂鋰合金設(shè)計(jì)及性能調(diào)控的代表性論文如下:[1]Tongzheng Xin, Yuhong Zhao, Reza Mahjoub, Jiaxi Jiang, Apurv Yadav, Keita Nomoto, Ranming Niu, Song Tang, Fan Ji, Zakaria Quadir, David Miskovic, John Daniels, Wanqiang Xu, Xiaozhou Liao, Long-Qing Chen, Koji Hagihara, Xiaoyan Li, Simon Ringer, Michael Ferry, Ultrahigh specific strength in a magnesium alloy strengthened by spinodal decomposition, Science Advances 7(23) (2021) eabf3039.[2]Song Tang, Tongzheng Xin, Wanqiang Xu, David Miskovic, Gang Sha, Zakaria Quadir, Simon Ringer, Keita Nomoto, Nick Birbilis, Michael Ferry, Precipitation strengthening in an ultralight magnesium alloy, Nature Communications 10(1) (2019) 1003.[3]Tongzheng Xin, Song Tang, Fan Ji, Luqing Cui, Binbin He, Xin Lin, Xiaolin Tian, Hua Hou, Yuhong Zhao, Michael Ferry, Phase transformations in an ultralight BCC Mg alloy during anisothermal ageing, Acta Materialia 239 (2022) 118248.[4]Song Tang, Zongde Kou, Tongzheng Xin, Zijian Zhang, Tao Feng, Ting Luo, Si Lan, Gerhard Wilde, Bin Jiang, Achieving high strength via solutes co-clustering and solvents redistribution in an ultralightweight BCC magnesium alloy, Materials Research Letters 11(7) (2023) 556-562.[5]Song Tang, Tongzheng Xin, Wanqiang Xu, David Miskovic, Chuanqiang Li, Nick Birbilis, Michael Ferry, The composition-dependent oxidation film formation in Mg-Li-Al alloys, Corrosion Science 187 (2021) 109508.