Q345q橋梁鋼和Q345qNH耐候鋼在模擬工業大氣+除冰鹽混合介質中的腐蝕行為

郭鐵明, 徐秀杰, 張延文, 宋志濤, 董志林, 金玉花

1.蘭州理工大學 省部共建有色金屬先進加工與再利用國家重點實驗室 蘭州 730050

2.蘭州理工大學材料科學與工程學院 蘭州 730050

Corrosion Behavior of Q345q Bridge Steel and Q345qNH Weathering Steel in a Mixed Medium of Simulated Industrial Environment Solution and Deicing Salt

GUO Tieming, XU Xiujie, ZHANG Yanwen, SONG Zhitao, DONG Zhilin, JIN Yuhua

1.State Key Laboratory of Advanced Processing and Recycling of Non-ferrous Metals, Lanzhou University of Technology, Lanzhou 730050, China

2.School of Materials Science and Engineering, Lanzhou University of Technology, Lanzhou 730050, China

摘要

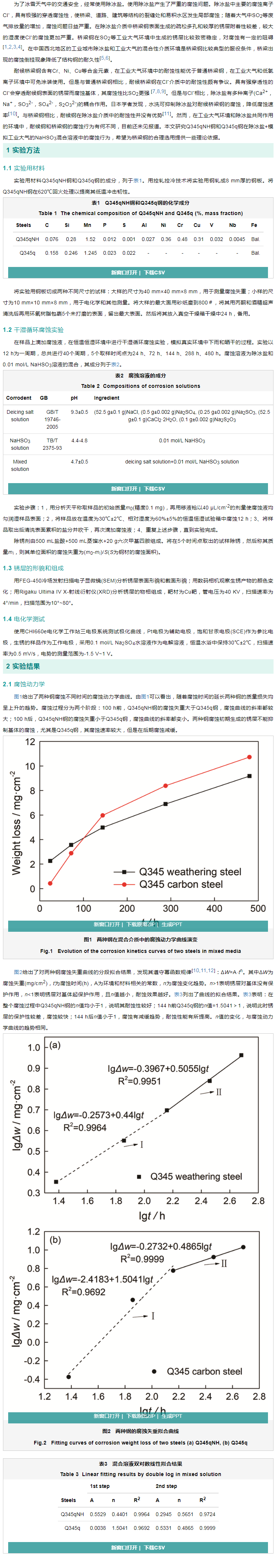

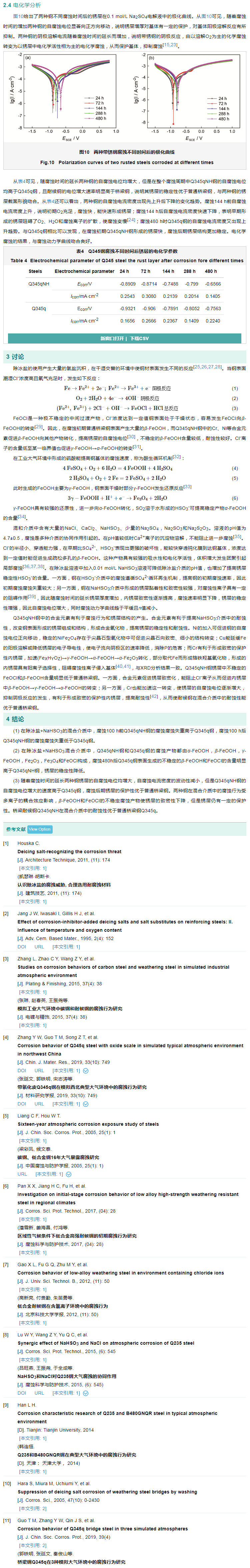

采用干濕循環加速腐蝕實驗,研究了Q345qNH耐候鋼和Q345q橋梁鋼在模擬西北地區工業大氣環境的腐蝕介質(除冰鹽+0.01 mol/L NaHSO3)中的腐蝕行為。用失重法研究了兩種鋼的腐蝕動力學曲線,并使用XRD、SEM 和電化學工作站等手段分析了兩種鋼腐蝕不同時間后銹層的物相、形貌結構及其電化學特性。結果表明:在除冰鹽+NaHSO3的混合介質中,Q345qNH鋼腐蝕100 h前的失重稍大于Q345q鋼,腐蝕100 h后橋梁鋼的失重量明顯大于耐候鋼;兩種鋼的腐蝕產物均由α-FeOOH,β-FeOOH,γ-FeOOH,Fe2O3,Fe3O4和FeOCl構成,但是Q345q鋼中生成的不穩定β-FeOOH和FeOCl的含量明顯高于Q345qNH鋼,銹層的穩定性降低;隨著腐蝕時間的延長兩種鋼銹層的自腐蝕電位均增大,自腐蝕電流密度均波動性減小,Q345qNH耐候鋼的自腐蝕電位增大的速度高于Q345q鋼,腐蝕后期其銹層的保護性優于普通橋梁鋼。兩種鋼在混合介質中的腐蝕行為受多離子的耦合效應影響,銹層的致密性因β-FeOOH和FeOCl等不穩定腐蝕產物的生成而降低,但是仍有一定的保護性。Q345qNH耐候鋼在除冰鹽+0.01 mol/L NaHSO3混合介質中的耐蝕性優于Q345q普通橋梁鋼。

關鍵詞: 材料失效與保護 ; 腐蝕行為評價 ; 干濕循環 ; 西北大氣環境 ; 橋梁鋼

Abstract

Corrosion behavior of Q345qNH weathering steel and Q345q ordinary bridge steel in a mixed medium of simulated industrial environment solution and deicing salt was investigated by means of wet/dry cyclic accelerated corrosion test, The corrosion kinetics curves of the two steels were studied by weight loss method, and the phase, morphological structure and electrochemical characteristics of the rust layer after corrosion of the two steels for different times were analyzed using XRD, SEM and electrochemical workstation. The results show that the corrosion weight loss of Q345qNH weathering steel is slightly higher than that of Q345q bridge steel before 100 h. However, after 100 h the corrosion mass loss of bridge steel is obviously larger than that of weathering steel. The corrosion products were composed of α-FeOOH, β-FeOOH, γ-FeOOH, Fe2O3, Fe3O4 and FeOCl, but the content of unstable β-FeOOH and FeOCl on Q345q bridge steel was significantly higher than that on Q345qNH weathering steel, thereby, the rust scale on Q345q bridge steel presented lower stability; the free-corrosion potential of the rust layer on the two steels increased with the increasing time, and the free-corrosion potential of Q345qNH weathering steel increased faster than that of Q345q bridge steel, while, their free-corrosion current density showed undulatory attenuation. The protectiveness of the rust layer of weathering steel was better than that of ordinary bridge steel in the later stage of corrosion; the corrosion behavior of the two steels in the mixed medium was affected by the coupling effect of various ions. Due to the existence of unstable corrosion products such as β-FeOOH and FeOCl, the compactness of the rust layer reduced, even so, which still maintained protectiveness to certain extent. In general, the corrosion resistance of Q345qNH weathering bridge steel in the mixed media was better than that of Q345q ordinary bridge steel.

Keywords: material failure and protection ; corrosion behavior evaluation ; wet and dry cycle ; northwest atmospheric environment ; bridge steel

免責聲明:本網站所轉載的文字、圖片與視頻資料版權歸原創作者所有,如果涉及侵權,請第一時間聯系本網刪除。

相關文章

官方微信

《中國腐蝕與防護網電子期刊》征訂啟事

- 投稿聯系:編輯部

- 電話:010-62316606-806

- 郵箱:fsfhzy666@163.com

- 中國腐蝕與防護網官方QQ群:140808414

點擊排行

PPT新聞

“海洋金屬”——鈦合金在艦船的

點擊數:7130

腐蝕與“海上絲綢之路”

點擊數:5741